Aerospace Company Turns to Axxis for High-Quality Precision Machining

Pivoting to New Markets

Over our 62 years in business, we have worked with a wide variety of industries. We’ve supplied businesses with high-quality machined parts and components, including those within the power generation, medical device, automotive aftermarket, and military industries. For our first 15 years in business, however, we worked solely with companies within the fluid and gas industry.

Eventually, we realized that our services could provide the same value to industries outside of fluid and gas. What once was 95% of our business, now makes up only 20% due to our expansion into other markets. In the last few years, Axxis has branched out into the aerospace market, as our shop is ideally situated to provide those within the aerospace industry with the precision machining quality they need to complete mission-critical work.

Challenge

Our customer, a company that designs, manufactures, and launches the world’s most advanced rockets and spacecraft, was in need of a precision machining facility to machine their high-temp alloys. They were having trouble finding a shop that would complete the work and found themselves being turned away quite frequently, as machining those materials tends to be more difficult than the typical scope of work for most shops.

Axxis, however, took on the challenge and the customer has come back repeatedly. “We found that companies within space exploration were a great fit for our shop, as we have a very high caliber quality and on-time delivery,” said Brian Grigson, General Manager at Axxis Corp. “To be in the space exploration industry, you have to be at a different level. The bar is higher for precision machining shops who are doing that kind of work.”

Solution

The customer was also experiencing machining ability problems internally. They looked to Axxis to help solve their problems, as it was taking their team a large amount of time to do the job in-house. We worked with our customer to take the burden of machining high-temp alloys off their plate which resulted in increased throughput and productivity.

“The customer has come back to Axxis repeatedly asking if we can do projects that other shops have refused to do,” said Brian. “It’s a huge compliment to us when they come back because it just goes to show that Axxis is making itself known as a precision machining leader within aerospace.”

Results

At the end of the day, the most significant contribution Axxis provided our customer with was the parts they needed in the time frame they wanted them in. When they were machining their parts internally, their lead time was 16 weeks. Axxis was able to cut it down to three weeks.

According to Brian, our customer continues to work with Axxis for a variety of other reasons, as well. “We’re open to sitting down and having conversations with them. It’s never a ‘we know best’ situation and they appreciate that,” he said. “We discuss what they’ve tried, what we’ve tried, and come up with a plan to accomplish the same common goal which is to machine the best part in the shortest amount of time.”

Once Axxis got in with one aerospace company and built a good rapport, our reputation carried throughout the industry. Now, we are doing work for multiple companies within space exploration, and many consider Axxis as their go-to for high-quality precision machining. Because of our expansion into the aerospace industry, we’ve developed relationships with buyers, planners, and other well-known industry leaders.

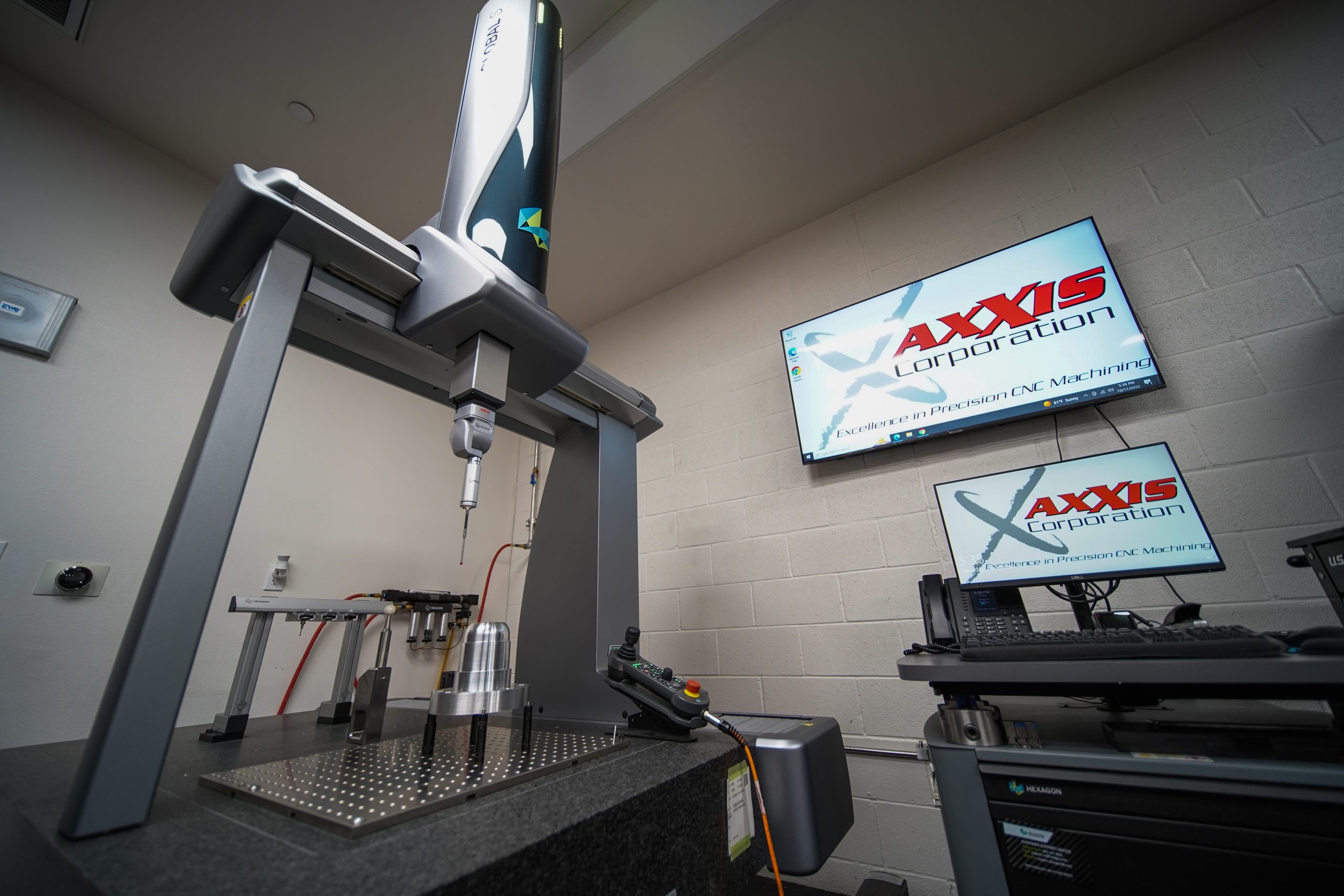

We are proud to provide our aerospace customers with assembly work, multi-step processes, and the ability to take their parts from the very beginning stages all the way to the finish line. At Axxis, quality and customer service are standard. What really sets us apart is our unbeatable reputation for outstanding customer service, our state-of-the-art facility, and our commitment to reinvesting in new machinery, so we can provide our customers with the results they’re looking for.

About Axxis

Established in 1959, Axxis Corp. is in the business of producing high-quality machined parts and components for use in many specialized industries including aerospace, power generation, fluid and gas measurement, medical device, automotive aftermarket, and military.

Our 40,000 sq. ft. facility is a full CNC machine shop that uses cutting-edge equipment and software for quickly manufacturing quality components. We offer a wide range of services from simple and advanced machining to finished products.

EQUIPMENT

Consistently high level of excellence in technology, products, and services.

CNC TURNING

View a list of the equipment and tooling we use for turning high quality parts and components

ALL CNC TURNING MACHINES

CNC MILLING

View the variety of cutting-edge machining centers and devices we use for milling precision parts

ALL CNC MILLING MACHINES

SUPPORT EQUIPMENT

View our state-of-the-art equipment list of support equipment, software and tools

ALL SUPPORT MACHINES