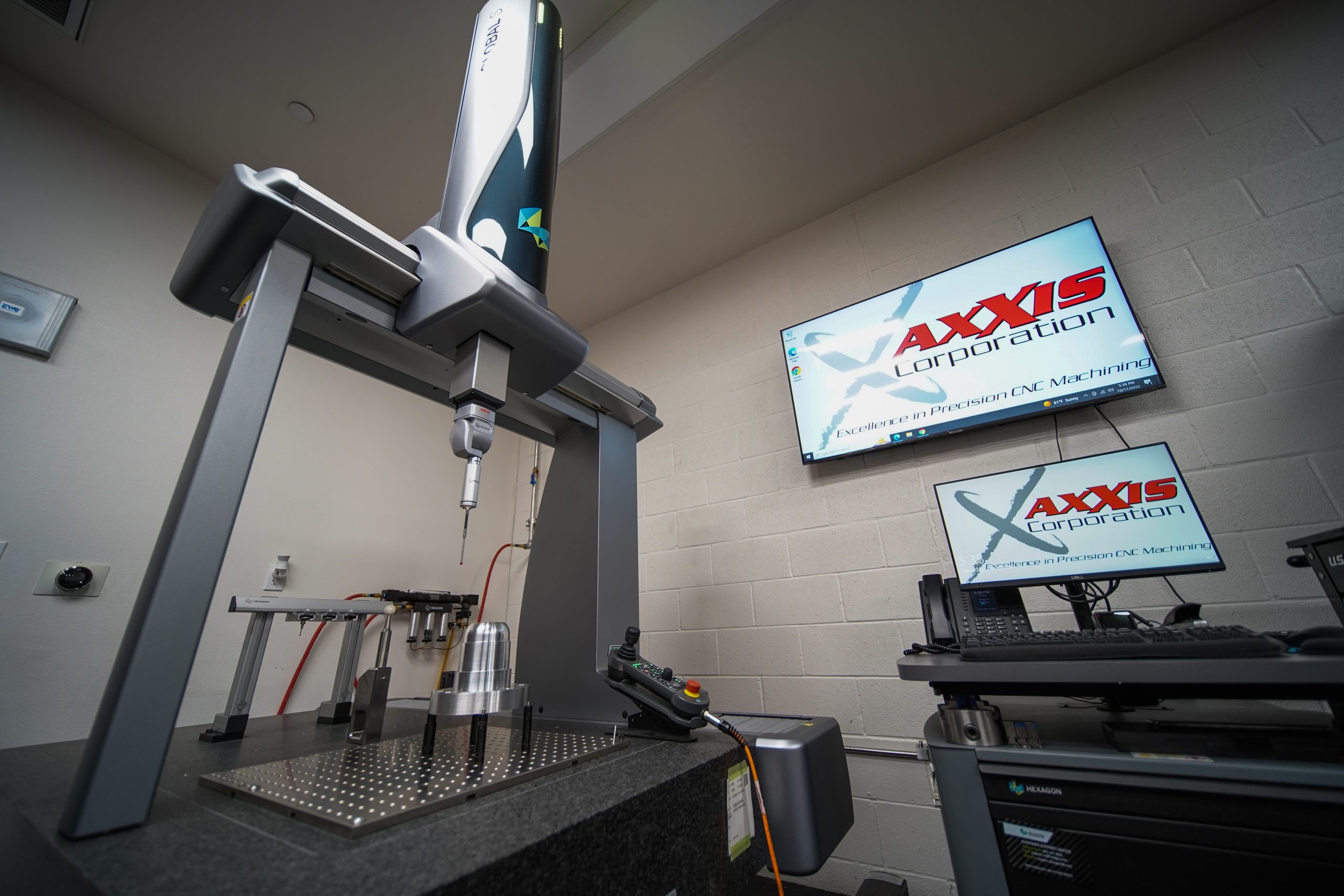

Axxis Corporation Invests in State-of-Art Equipment to Enhance Product Quality

Perris, California – January 9, 2022 – Axxis Corporation is pleased to announce the investment of state-of-art equipment at their headquarters facility in Perris, California. Brian Grigson, General Manager, exclaimed, “we have the newest technology for manufacturing quality components. Our state-of-the-art facility includes 40,000 square feet of cutting-edge equipment and software. We utilize Solid Works and Esprit CAD/CAM systems for programming. Our equipment list reflects our goal to provide machining that is reliable, accurate, and of the highest quality.”

Technology change in the machine shop industry has always been driven by its high-tech markets. In addition to medical device manufacturing, these include defense and aerospace markets. Demand has picked up for machined products from these sectors over the past five years and technology, in terms of processes and products, has improved as a result. Other factors driving technological advancement for machine shops include the need to machine newly developed materials, changing government regulation, demand from customers for higher productivity and reduced cycle time to keep prices down. A common theme across the industry’s markets has been the need to deliver more volume in less time. Grigson further went on to explain, “it has become a high priority to consistently evaluate our technology to make sure we are meeting our clients’ needs and working with them to take their products to even higher levels.”

Grigson continued, “with the investment of seven-axis and five-axis machines we have added in more automation and tighter tolerances to the implant and device manufacturing market, for instance.” Furthermore, when discussing why their high value partners continue to return, “we’re open to sitting down and having conversations with them. It’s never a ‘we know best’ situation and they appreciate that,” he said. “We discuss what they’ve tried, what we’ve tried, and come up with a plan to accomplish the same common goal which is to machine the best part in the shortest amount of time.”

They are ISO 9001:2015, ISO 13485:2016, FFL approved and are committed to a high level of excellence in technology, products, and services. They are constantly upgrading both our equipment and personnel training to meet the ever-changing technological demands of our industry. Their full list of equipment is evidence of their goal to provide machining that is reliable, and accurate with the newest technology. With the utilization of Solid Works and Esprit CAD/CAM systems for programming they can offer diversified services that conform to or surpass clients’ design requirements.

About Axxis

Established in 1959, Axxis Corp. is in the business of producing high-quality machined parts and components for use in many specialized industries including aerospace, power generation, fluid and gas measurement, medical device, automotive aftermarket, and military.

Their 40,000 sq. ft. facility is a full CNC machine shop that uses cutting-edge equipment and software for quickly manufacturing quality components. They offer a wide range of services from simple and advanced machining to finished products.

EQUIPMENT

Consistently high level of excellence in technology, products, and services.

CNC TURNING

View a list of the equipment and tooling we use for turning high quality parts and components

ALL CNC TURNING MACHINES

CNC MILLING

View the variety of cutting-edge machining centers and devices we use for milling precision parts

ALL CNC MILLING MACHINES

SUPPORT EQUIPMENT

View our state-of-the-art equipment list of support equipment, software and tools

ALL SUPPORT MACHINES