Axxis Solves Quality Inspection Bottleneck with Top-of-the-Line CMM

Axxis Solves Quality Inspection Bottleneck with Top-of-the-Line CMM

Every business faces internal problems at one point or another; however, the best companies are constantly in a problem-solving mode. Axxis is no exception.

Challenge

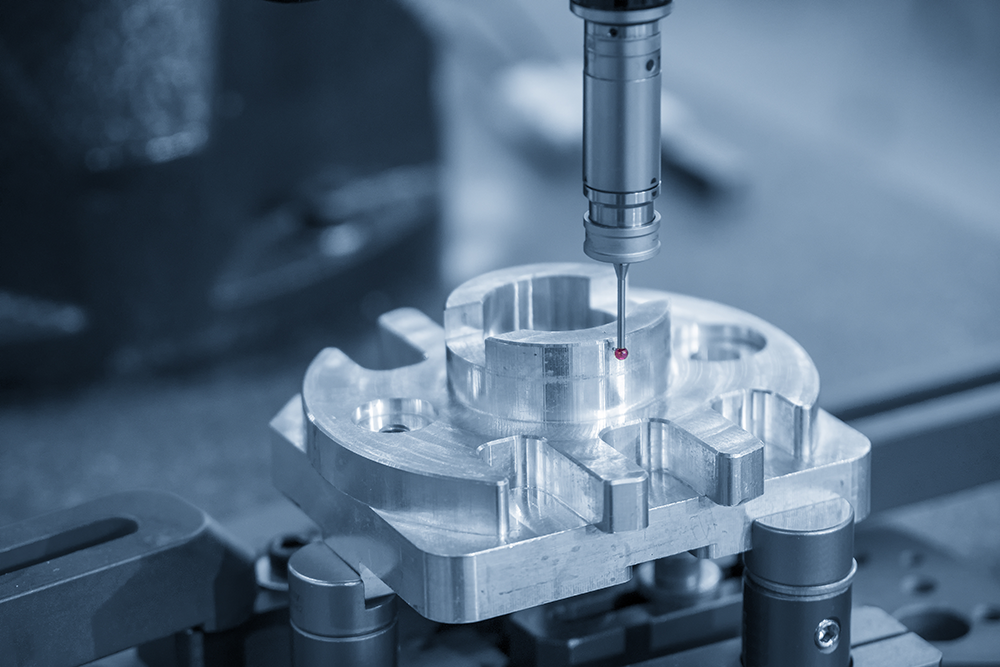

We were facing difficulty when it came to maintaining a good quality to speed balance, resulting in a slight backlog during the quality inspection process. When analyzing this bottleneck, we determined that it was due to insufficient coordinate measuring machine (CMM) equipment and software training which ultimately led to reduced throughput throughout our quality department.

When Axxis worked primarily with customers in the Oil & Gas industry, CMM machines weren’t required to inspect the parts we were making. However, as we started working more within the space exploration market, each part we made required a CMM inspection report. Eventually, this led us to realize that a bottleneck was forming in our quality department, causing a capacity restraint and the inability to take on extra work.

Solution

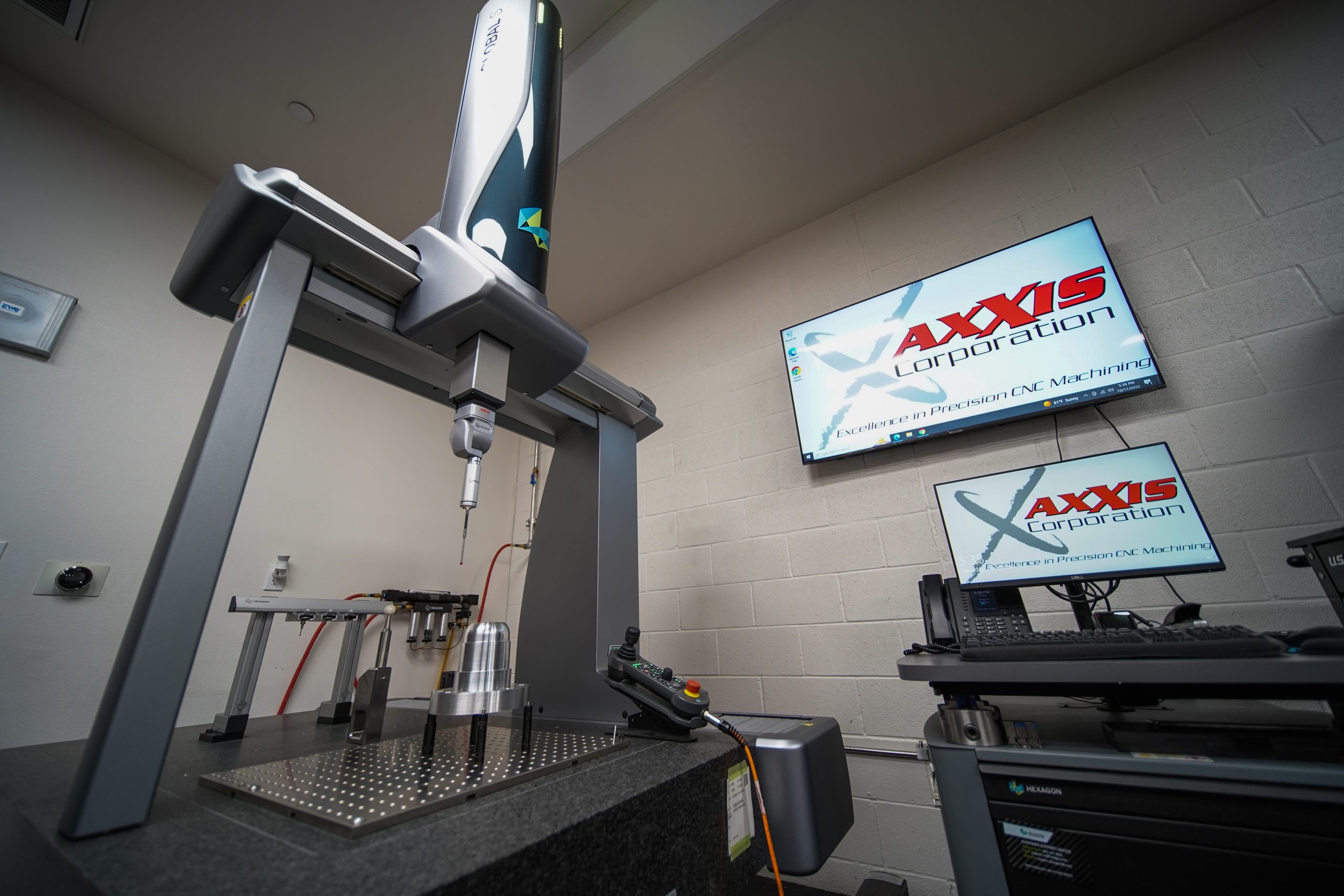

Although we had a CMM at the time, it was outdated and unable to process the influx of orders due to our growth in the space exploration industry. We recognized we needed to do something about it, so we decided to invest in a new CMM and a four-month-long training course for our quality team to get them thoroughly familiar with the software. While we received multiple quotes for various machines, we chose the GLOBAL S Green 7.10.7 CMM by Hexagon.

“Price didn’t necessarily matter to us when deciding on a new CMM,” said Brian Grigson, General Manager at Axxis Corporation. “The quality of the machine and the customer service that comes with it were our top priorities.” Hexagon’s machine has far exceeded our expectations. In addition, their customer support center is located in central California, so in the rare occurrence of an issue, their team is highly responsive and can be at our facility the same day to resolve it.

Results

Since incorporating the new CMM into our quality inspection process, Axxis has been able to triple the amount of work that goes through our quality department. In addition, we reduced manual inspection significantly and are currently saving our quality team multiple hours each day by putting everything on the CMM. “Some parts require a 100% inspection on multiple dimensions. Before, if we had to do it manually, it took a long time,” Brian said. “Now, with the CMM and the programs that are written, that time has been cut down by 60%.”

In addition to the resolved capacity restraint, the new CMM allows Axxis to expand our business into more technical industries and provide enhanced precision. As a result, we can take on more work and provide more detailed reports to our customers. And, because the CMM takes video of the parts getting inspected, our customers can physically watch how we check their parts.

Axxis is proud of our commitment to continually investing in top-grade equipment and evolving with the various industries we serve. “We feel that if you’re not investing in new machinery and planning for the future, you’re doing a disservice to your customers and your employees,” Brian said. “In our minds, it’s a necessity that our employees are trained on top-of-the-line equipment because it keeps us competitive and gives our customers the best quality parts.”

About Axxis

Established in 1959, Axxis Corp. is in the business of producing high-quality machined parts and components for use in many specialized industries, including aerospace, power generation, fluid and gas measurement, medical device, automotive aftermarket, and military.

Our 40,000 sq. ft. facility is a full CNC machine shop that uses cutting-edge equipment and software for quickly manufacturing quality components. We offer a wide range of services from simple and advanced machining to finished products.

EQUIPMENT

Consistently high level of excellence in technology, products, and services.

CNC TURNING

View a list of the equipment and tooling we use for turning high quality parts and components

ALL CNC TURNING MACHINES

CNC MILLING

View the variety of cutting-edge machining centers and devices we use for milling precision parts

ALL CNC MILLING MACHINES

SUPPORT EQUIPMENT

View our state-of-the-art equipment list of support equipment, software and tools

ALL SUPPORT MACHINES